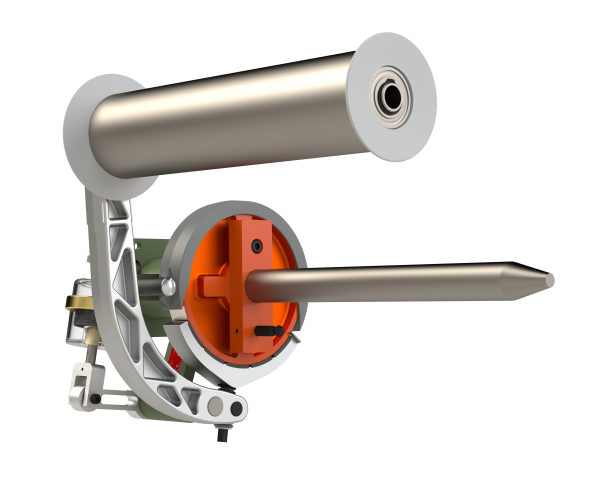

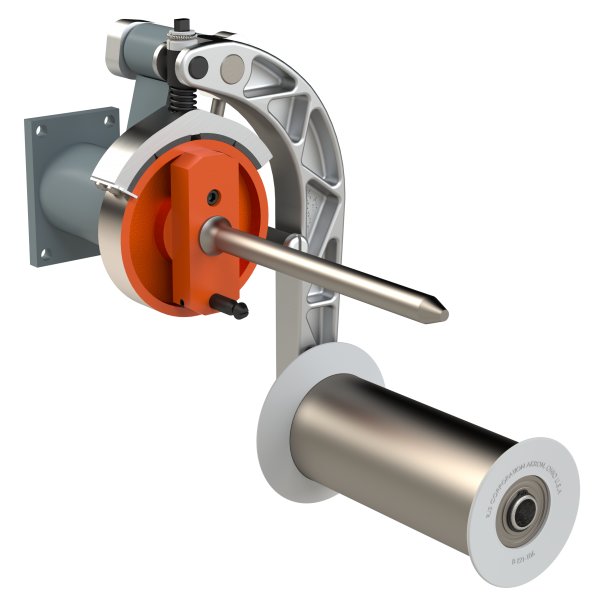

The Tension Controller is the most important component in the creel system with each controller holding a spool of steel cord while providing a consistent tension as the cord is pulled by the calender. RJS Tension Controllers are air-actuated for horizontal take-off with the tension remaining substantially constant from full spool to empty requiring no adjustment. Because the air pressure applied is the same for all units, the tension variation from one controller to the other is minimal when cord diameter is constant.

In 1975, Raymond Slezak, one of the founders of RJS Corporation patented the fundamental design for its sentinel tension controller for the dispensing steel cord for radial tire production. Today, RJS offers a variety of tension controllers based on this concept to accommodate a range of configurations, tensions, spool sizes and materials across several different industries. Our standard series can be configured to handle B-80/33 and/or B-60 spools or B-80/17 and/or B-40 spools. Key features include:

Simple Pneumatic Actuation

Cord tension is adjusted by changing the air pressure of a common air supply to all controllers at either a manual or automatic control console. Once a system is fully charged to the desired air pressure, no further air consumption is required.

Wire Tension Uniformity

RJS tension controllers are force-balanced, mechanical devices. Tension uniformity is assured when all units are supplied with the same air pressure and the wire spools and package content are the same diameter. The tension has a small variation as the full spools unwind and the wire package diameter becomes smaller.

Enduring Quality

The RJS tension controller is designed for long-lasting performance. The standard brake shoe friction material available on all RJS controllers represents the result of many hours of testing to find a friction material which maintains constant dynamic and static characteristics throughout an extended lifetime.